- Products

-

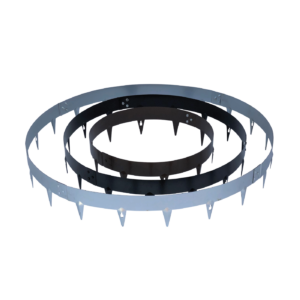

CORE EDGE Flexible Steel Edging & Tree Rings

-

CORE DRIVE Gravel Driveway Stabiliser

-

CORE Tree Root Protection ‘No Dig’ Construction

-

CORE DATUM EDGE NEW: Heavy Duty Landscape Edging

-

CORE COMMERCIAL Heavy Duty Gravel Stabiliser

-

CORE DRAINAGE Drainage Cells & Board

-

CORE PRO EDGE Aluminium Landscape Edging

-

CORE PATH Gravel Pathway Stabiliser

-

CORE WATER CRATE Soakaway & Attenuation Crates

-

Screens By CORE Decorative Screens

-

CORE GRASS Grass Reinforcement & Protection

-

CORE GEOSYNTHETICS Geogrids & Geosynthetics

-

Light Towers For Internal & External Use

-

CORE EQUESTRIAN Specialist Equine Surfacing

-

CORE GLOW Glow In The Dark Aggregates

-

- Case Studies

- About

- Knowledge Centre

DownloadsProduct Brochures

Cpd’s & TrainingContinuing Professional Development

Latest NewsExpertise and resources to provide specifiers

Meet the TeamThe faces behind the team at CORE

TestimonialsRead all our testimonials from Trustpilot

SectorsDiscover CORE products perfect for your sector.

- Stockists

- Contact

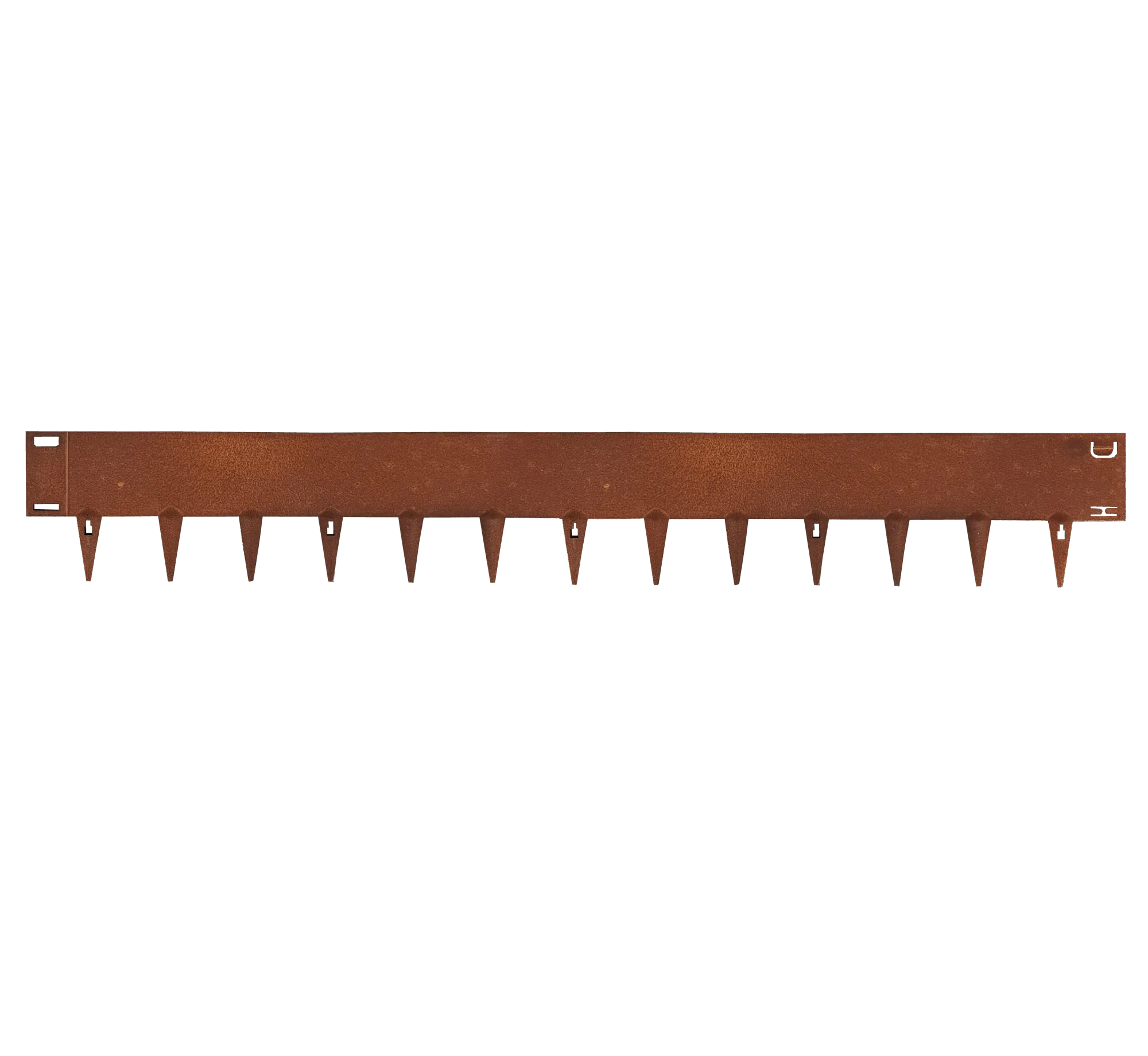

CORE EDGE HD XL – Long Lengths – Trade Edging – 2.5mm thick (2275mm) Single Length

Have you considered the CORE EDGE HD SHORT edgings?

To speak to a member of the telephone sales team please call us on 0800 118 2278.

Benefits of using Heavy Duty Steel Edging

- Our heavy-duty flexible steel edgings will not rust or flake, and they will not shatter if caught with a strimmer or mower.

- They have no sharp edges and a dual lock mechanism to secure each section.

- Simply tap into the ground to form the perfect edge restraint that will quite frankly last for decades.

- The face and the ground spike are formed from a single piece of steel.

- The spike has a unique fold along its centre to provide maximum strength. Reinforcing the spike, making it ideal for use in tougher ground conditions.

- In addition, if the soft ground is encountered, a rebar extension simply clips through the ground spike to provide additional stability.

- Easy to form perfect corners by hand and flexible enough to create perfect curves.

- They simply tap into the ground to form the perfect curved, straight or angled edge restraint.

- No specialist tools required and is available in a range of face/width combinations and finishes.

Weathered Steel

Our ASTM A588 weathering steel has a unique look. The naturally oxidizing finish makes it especially desirable for many architectural projects. Weathering steels are a group of steel alloys developed to remove the need for painting. Over time they form a stable rust-like appearance if exposed to the elements.

Made popular by the U.S Steel Co. and best-known under the US trademark COR-TEN®. They resist the corrosive effects of all types of weather. By forming a coating of dark brown oxidation over the metal. In simple terms, the steel is allowed to rust and that rust forms a protective coating that slows the rate of future corrosion.

AkzoNobel Powder Coated Heavy Duty Flexible Steel edging

The galvanised steel edgings are finished with a 110-micron polyester powder coating that is designed for external use. This coating prevents colour fade from UV exposure. It also forms a weather-resistant barrier guaranteeing a 20+ year product life.

The AkzoNobel coating is applied electrostatically and is then cured under extreme heat to allow it to flow and form a skin. This skin creates a hard-wearing flexible finish that is tougher than conventional paint and improves scratch resistance.

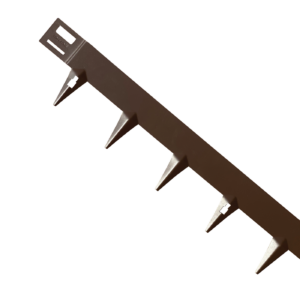

Secure Connecting Mechanism

The CORE Edge dual locking mechanism provides a rigid connection between adjoining edges on our Heavy-duty flexible steel edging. Helping to provide an almost seamless connection.

Using a pair of thin-nosed pliers pull both of the thin tabs through the slit in the adjacent edging and rotate them back on themselves.

Once connected if more hands are available, pre-joined edges can be installed as one continuous length. Making it far easier to create larger curves or complex shapes.

Optional Spike Extension

This ingenious spike extension can be retrofitted to the edging after the edging is installed.

If any softer ground is encountered:

- Simply look back at your installed edging, if you notice any that appear to be unstable or leaning over slightly, just scrape back some soil from around the top of the spike to reveal the hole in the spike that houses the extension clip.

- Insert the clip through one of these preformed holes, and place your foot against the edging to hold it upright.

- Locate a pin into the clip and drive the pin into the ground using a mallet.

- The clip expands as the pin passes through creating a secure connection with the edging and providing the additional support required.

Add these suggested products to your order

Copyright CORE 2025 Website design and marketing by Unity Online